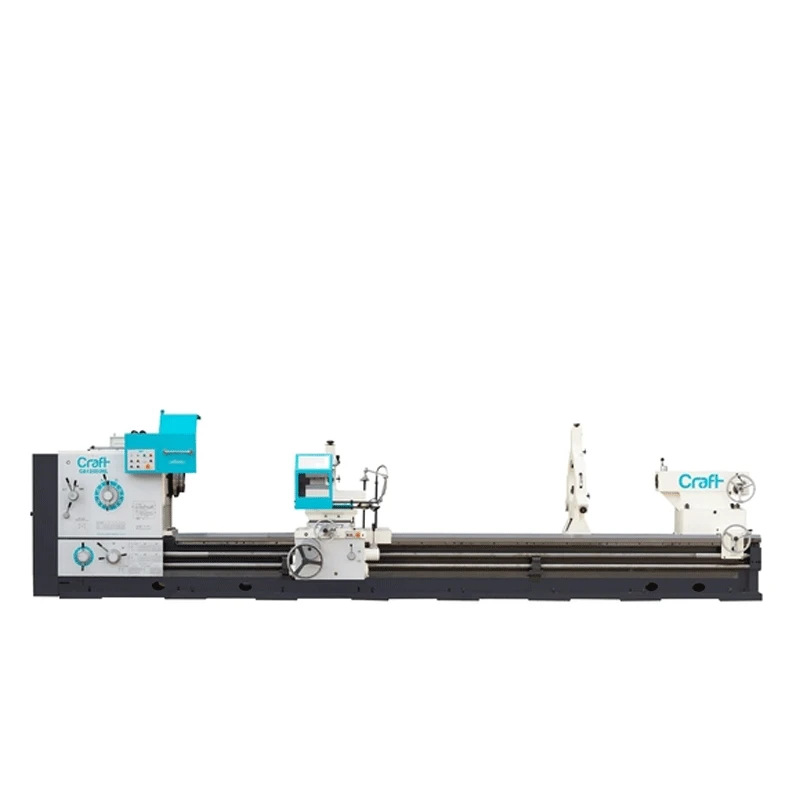

Large Diameter Lathe Machines

CA20060DL Heavy Duty Lathe

Optimise your production processes and make your business more competitive with precision machining, fast production and a wide range of materials.

Customer Orientated Solutions

With our customer satisfaction orientated approach, we are here to understand your needs and provide the most suitable lathe. Our experienced team utilises the latest technology and know-how in the industry to develop customised solutions. Contact us to increase the potential of your business and maximise productivity.

TECHNICAL SPECIFICATIONS

| Motor Power | 30 kW, 400 V |

|---|---|

| Diameter Over the Counter | 2000 mm |

| Car Diameter | 1650 mm |

| Bank Width | 1100 mm |

| Distance Between Centers | 6000 mm |

| Maximum Load Capacity | 16000 Kg |

| Speed | 3.15-315 (forward) / 3.5-291 (reverse) rpm |

| Grade | 21 (forward) / 12 (backward) |

| Tip of Lantern Shaft | A2-15 |

| Diameter of Lantern Shaft | 130 mm |

| Enine Support Movement | 900 mm |

| Cross Support Movement | 360 mm |

| Gezer Tailstock Taper | M80 |

| Gezer Tailstock Diameter | 260 mm |

| Gezer Tailstock Movement | 300 mm |

| Linear Feeding | 0.1-12 (56 units) mm/dev |

| Transverse Feed | 0.05-6 (56 pieces) mm/dev |

| Metric Pitch Ratio | 1-120 (44 units) mm |

| Inch Pitch Ratio | 0.25-28 (31 pieces) |

| Module Pitch Ratio | 0.5-60 (45 pieces) |

| Diametric Pitch Ratio | 0.5-56 (38 pieces) |

| Pencil Case Size (max.) | 50x50 mm |

| Machine Size | 900x2200x2600 mm |

| Weight (Kg) | 22,000 |